3D Anatomy - Frugal Innovation

Thesis project 2016-17: +LAB, Thesis in Design & Engineering

Student: Ravalli Giuditta

The purpose of this project, in addition to the great demonstration value, is the representation of the human body structure divided into parts, through the 3D printing of ‘patient-specific’ anatomical models for medicine and surgery.

This application is particularly useful for pre-operative practice, for teaching and understanding the human body,

and thanks to the versatility of 3D printing the case studies become unlimited.

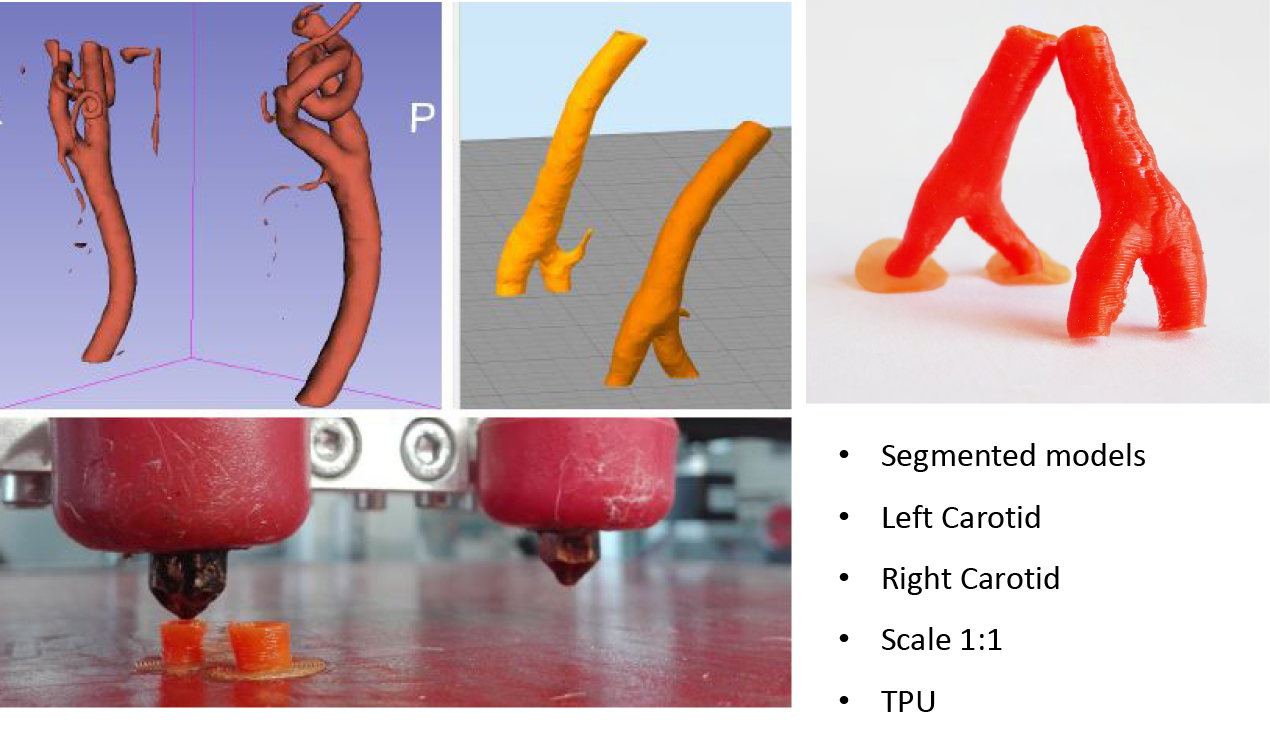

The carotid artery 3D model were obtained from DICOM files, creating the so called ‘patient-pecific' model,

that has the real shape and the real defects of the patient.

www.piuability.it/blog/medicina/anatomia-in-3d

Frugal innovation:

An important aspect is the “Frugal Innovation” approach: the “art of doing more with less” has allowed the exploitation of low cost 3D printers, softwares and materials and to obtain anatomical models with high quality and low price, cheaper than the anatomical models currently on the market.

All the artery models were 3D printed without support materials, to simplify the finishing proces, and to hve a higher surface quality.

Carotid artery.

The first model obtained from a DICOM file is the carotid bifurcation, considering both the left and right vessel.

From the DICOM file is possible to select the desired volume, and once the selection is finished, it's possible to create the 3D model in the .stl format.

The stl obtained must be finished and checked to verify the printability.

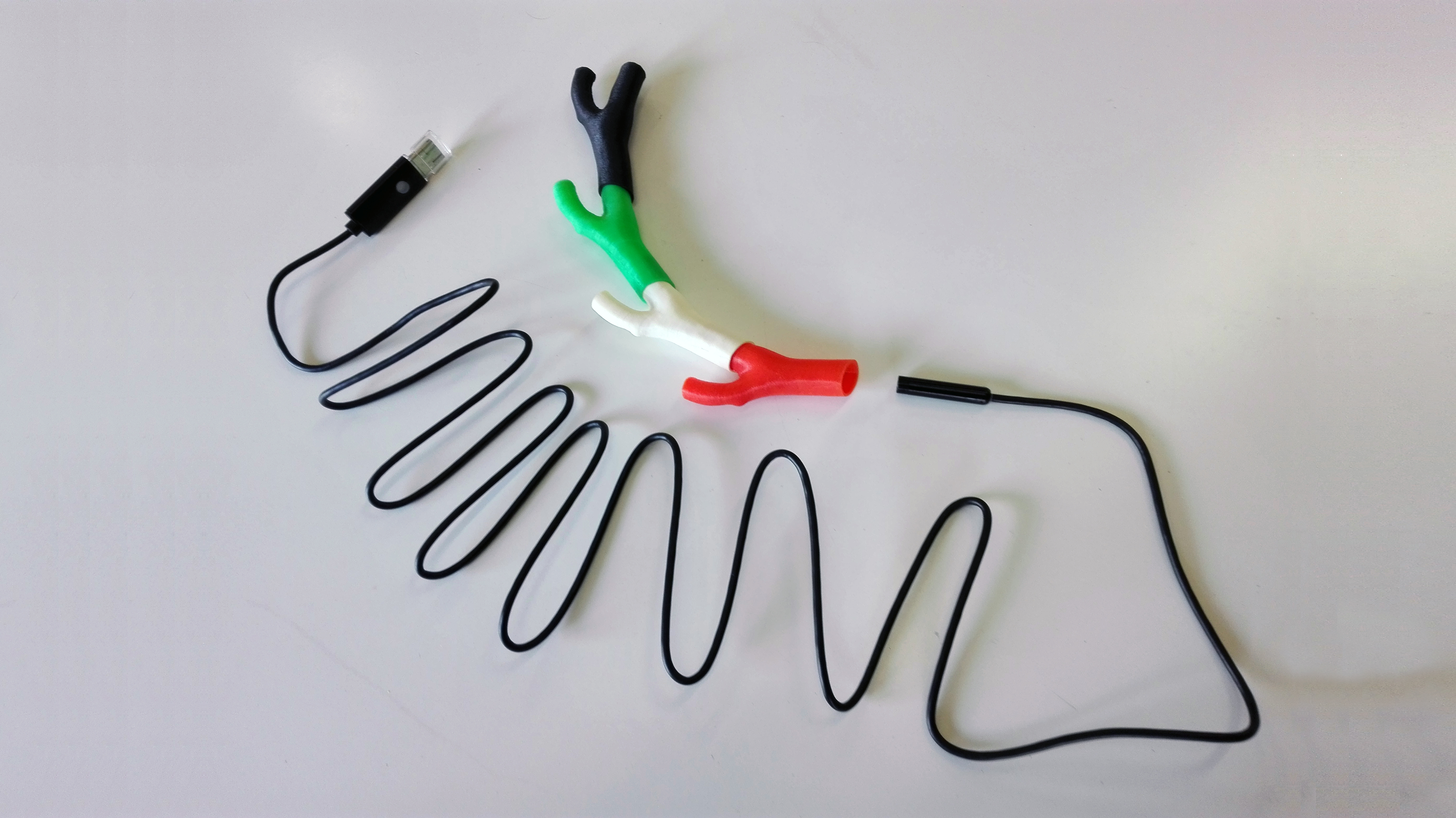

I achieved to 3D print the carotid model with different flexible materials, in different scales.

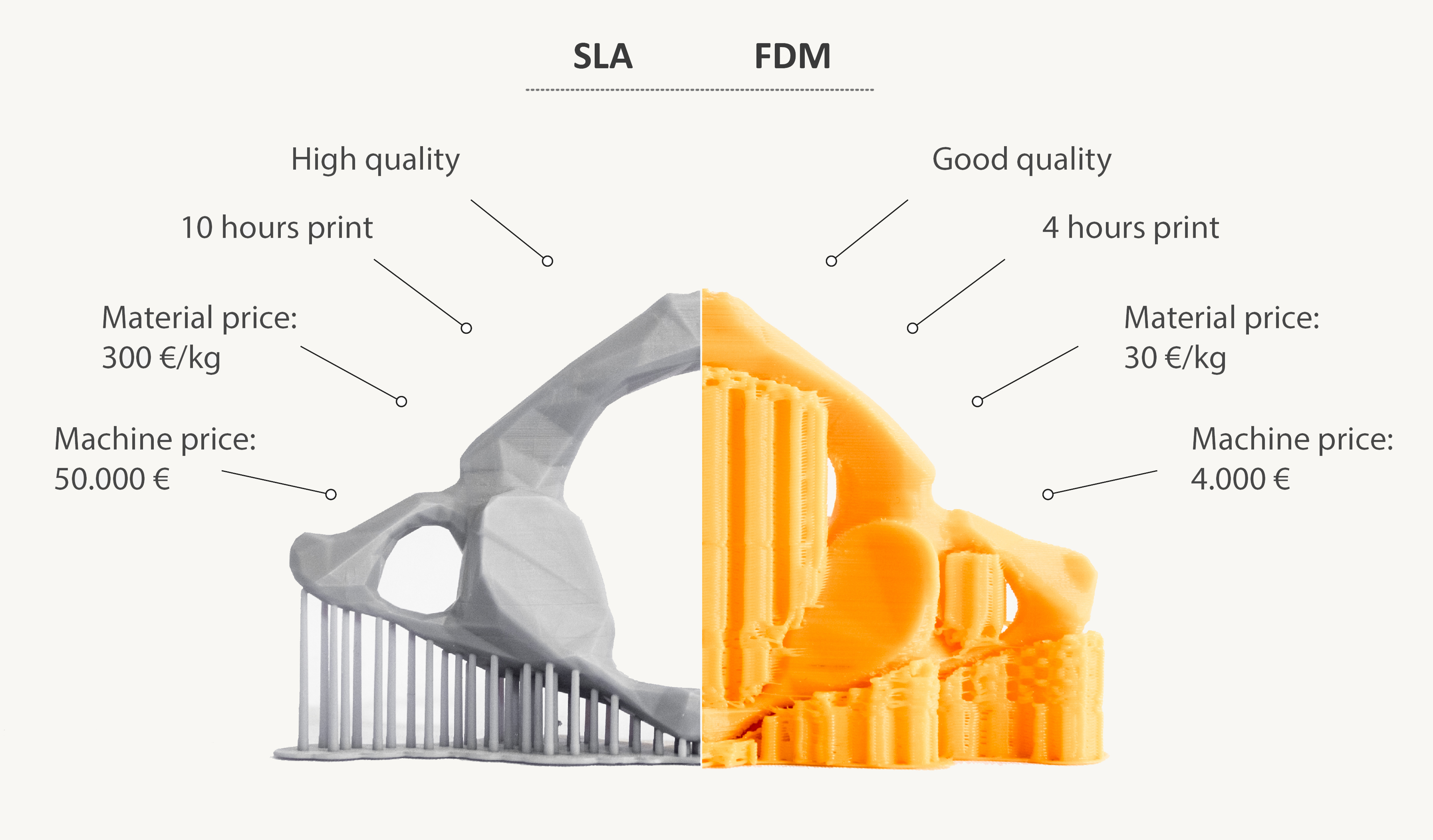

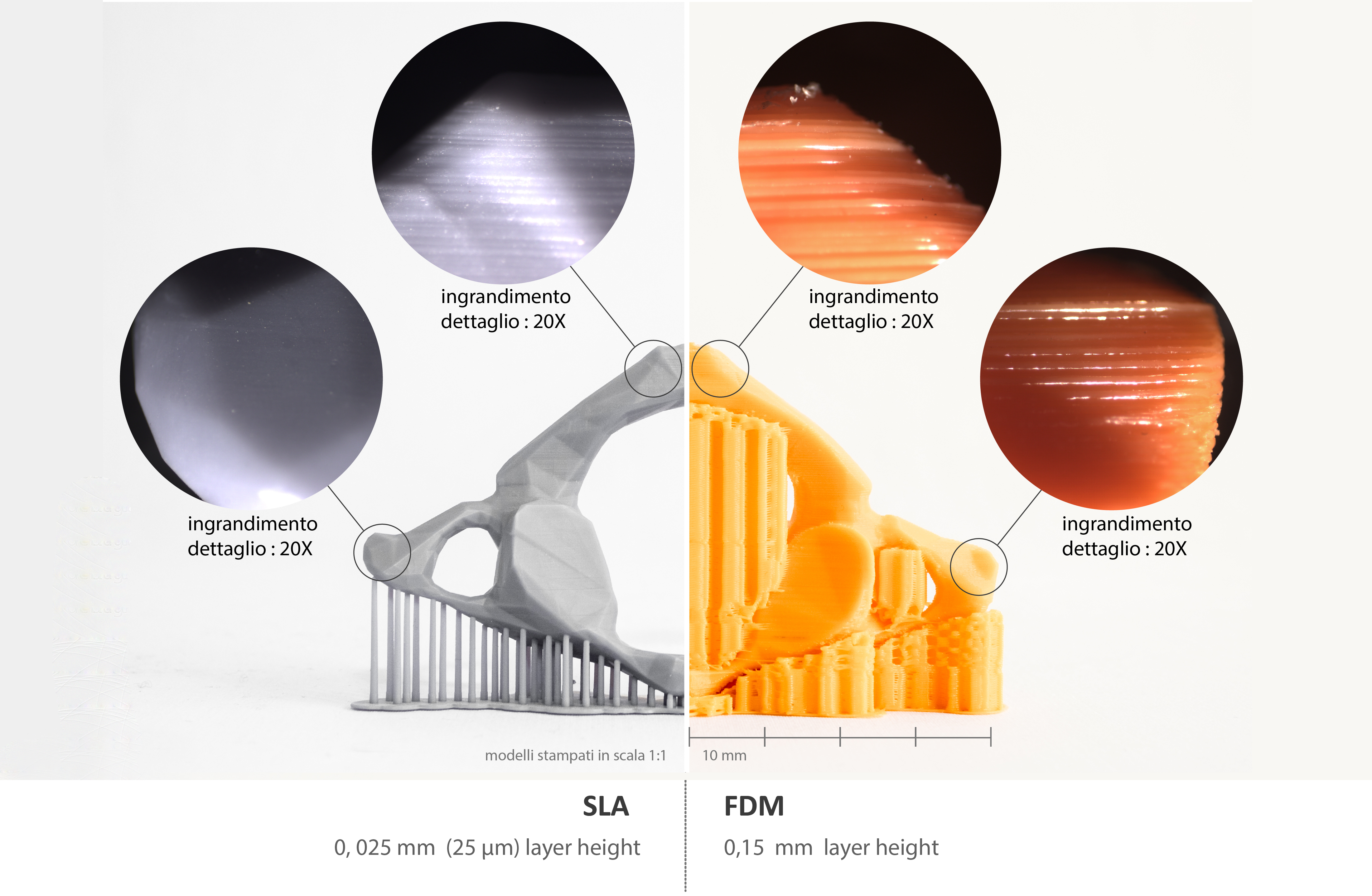

The 3D printing technology used is the FDM, Fused Deposition Modeling, instead of using the Stereolithography, SL.

The objective is to compare the two technologies and to see if a Frugal Approach can reach a good quality.

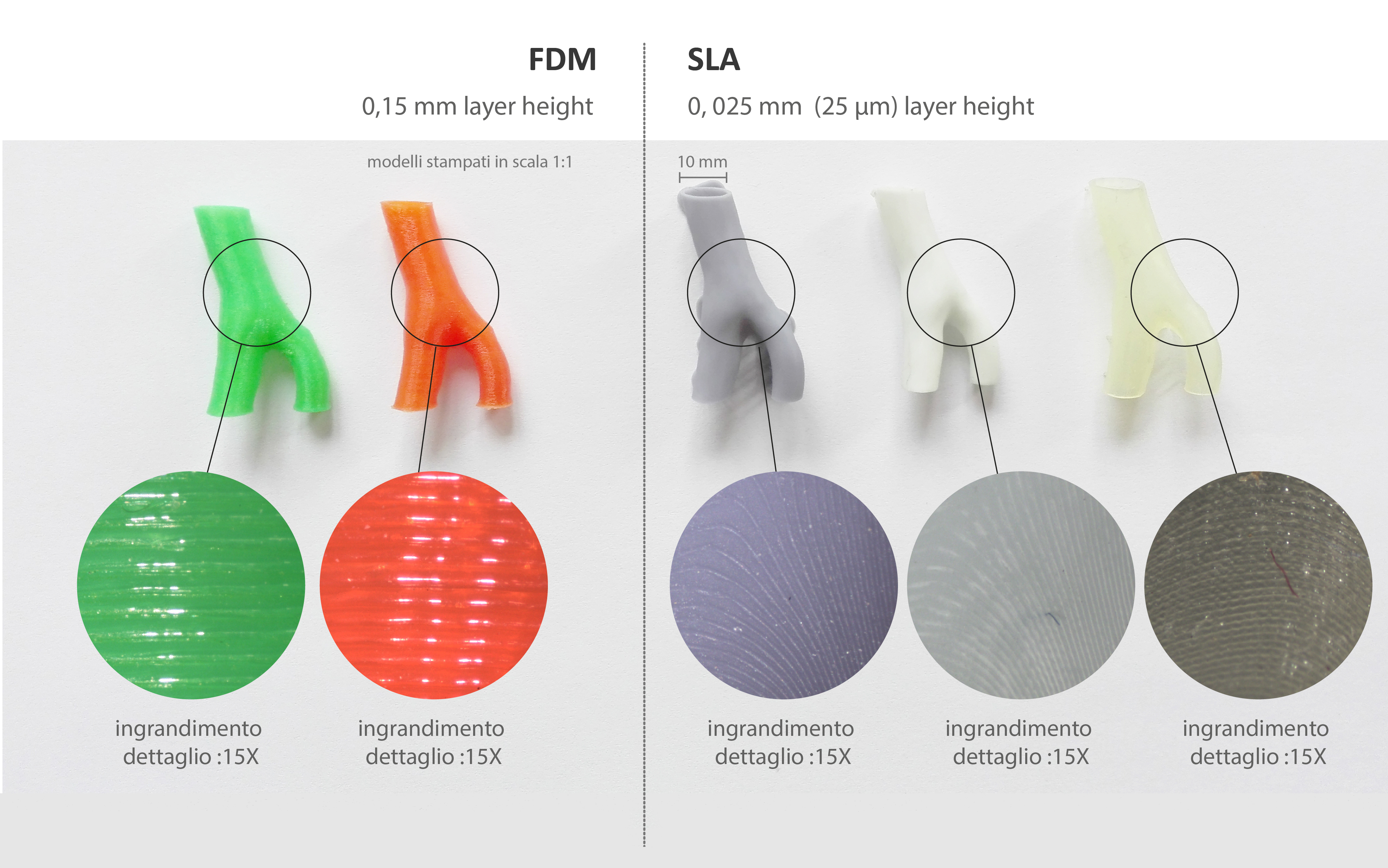

Carotid bifurcation 3D printed with FDM technology, with three different materials.

Carotid bifurcation 3D printed with SL technology, with three different materials.

Femoral artery.

The second model considered is the femoral artery .

In this case I had an existing patient/ specific model, in particular the artery was a pathological case.

I achieved to 3D print the carotid model with different flexible materials, in different scales.

The femoral artery model was a pathological case, and I used two extruders in order to 3D print the blood vessel with a flexible material, and, at the same time, the plaques with rigid materials, in order to give the anatomical model a mechanical properties and a pathological condition similar to the real one.

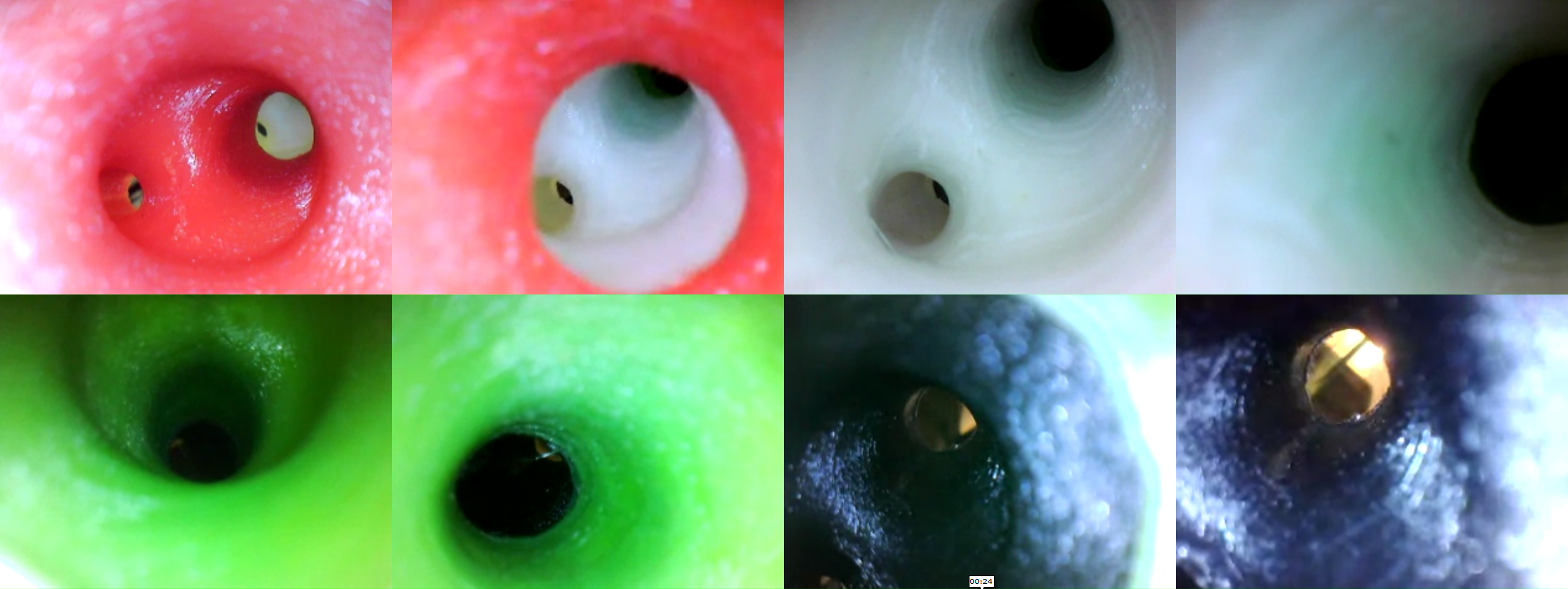

I used the 3D printing parts to make some simulations.

First the simulation of the passage into the vessel with an endoscope.

Then we simulate the angioplasty operation, so we inflate the angioplasty balloon into one of the 3D printed vessels, and the 3D printed part followed the baloon without any problem.

Lumbar vertebrae.

The 5 lumbar vertebrae were reconstructed from the TAC of an anonymous patient.

The obtained 3D models have shapes and imperfections corresponding to the real case, and this is very useful for surgeons, in order to make realistic practice and facilitate the preoperative planning phase of the surgery, reducing the times and operating risks.

All the vertebral models were 3D printed with rigid materials, PLA, while the intervertebral disks were 3d printed with flexible materials.

Vertebral column.

The vertebral column were downloaded from the internet.

All the vertebral models were 3D printed with rigid materials, PLA,

while the intervertebral disks were 3d printed with flexible materials.

Quality comparison.

From the comparison between the same model 3D printed with both the two different technologies, the Fused Deposition Modeling, or FDM, that is our low-cost choice, and the more expensive Stereolithography, or SL, we can see that we achieved a good quality, comparable to the SL one.

Cost comparison.

From the cost comparison between the anatomical models 3D printed in this study and some anatomical models available online, we can see that not only we achieved a good quality, but with this project we were able to lower the costs..